OMAX Waterjet

OMAX 55100 Waterjet

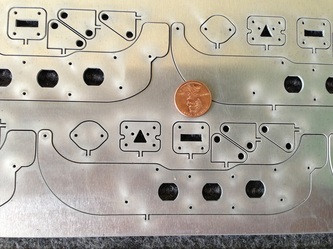

Our Waterjet has a 55" X 100" cutting envelope. Even though our Waterjet has a large cutting envelope, we can Waterjet down into the micro Waterjeting with our mini Waterjet head.

Our Waterjet can cut through granite, marble, tile, rubber, wood, glass, all metals, vinyl, and everything in between. The Waterjet's cutting envelope is 55"x100" and up to 8" thick, and can take virtually any CAD format.

Advantages of the Waterjet include:

- No heat zone is created. There is absolutely no problem if cutting hardened steel, stainless steel, ware plate, or tool steel.

- No discoloration on the cutting edge, as happens on brass or stainless steel when using a Laser or Plasma cutter.

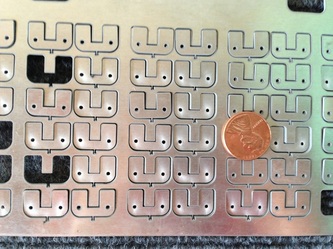

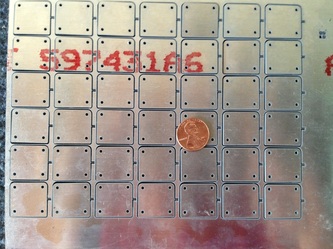

- With nesting software, material waste is held to a minimum.

- The Waterjet mixes water and garnet to cut through the materials, which results in a very clean cut and little to no burring.

Equipped with Tilt-A-Jet™ technology, which minimizes taper, the Waterjet can hold tighter tolerances, and eliminate a second operation machining, in most cases. Waterjetting is also a faster way to remove bulk material, so final machining only needs a fine cut to bring into print.

Our designer can help answer any questions or concerns you may have, you can find all information for emails and phone numbers under our Contact Us.

Waterjet Parts

Web Hosting by StartLogic